Exploring the realm of fleet maintenance errors and their solutions, this piece invites readers into a world of insightful knowledge, promising a reading experience that is both informative and engaging.

Delve into the subsequent paragraph for a detailed exploration of the topic.

Common Fleet Maintenance Mistakes

Effective fleet maintenance is crucial for ensuring the smooth operation of a fleet. However, there are common mistakes that fleet managers often make, which can have serious consequences on the overall efficiency and safety of the fleet.

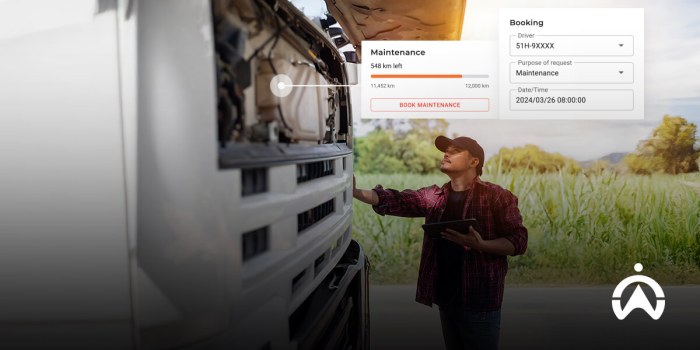

1. Neglecting Regular Inspections and Maintenance

One of the top mistakes made by fleet managers is neglecting regular inspections and maintenance schedules. When routine checks are not performed, issues with vehicles may go unnoticed and lead to breakdowns or accidents.

- Consequence: Increased downtime, repair costs, and potential safety risks for drivers.

- Example: A fleet manager fails to schedule regular oil changes for the vehicles, resulting in engine failure during a delivery, causing delays and added repair expenses.

2. Ignoring Driver Feedback and Reports

Another common mistake is ignoring feedback and reports from drivers regarding vehicle issues or maintenance needs. Drivers are often the first to notice any abnormalities and their input is valuable for preventive maintenance.

- Consequence: Unresolved issues leading to breakdowns on the road, affecting delivery schedules and customer satisfaction.

- Example: A driver reports strange noises coming from the brakes, but the fleet manager dismisses it. Eventually, the brakes fail, causing an accident and reputational damage to the company.

3. Using Incorrect Parts or Equipment

Using incorrect parts or equipment during maintenance or repairs can compromise the performance and safety of the vehicles. It is essential to use the right components specified by manufacturers.

- Consequence: Reduced vehicle efficiency, potential safety hazards, and voided warranties.

- Example: A maintenance technician installs a cheaper, generic air filter instead of the recommended one for a vehicle, leading to engine damage and decreased fuel efficiency.

Lack of Preventive Maintenance

Preventive maintenance is crucial in fleet management as it involves regular inspections, servicing, and repairs to prevent breakdowns and costly repairs down the line. By proactively maintaining vehicles, fleet managers can ensure optimal performance, increase vehicle lifespan, and enhance overall safety.

Essential Preventive Maintenance Tasks

- Regular oil changes: Ensuring proper lubrication of engine parts to prevent wear and tear.

- Tire inspections and rotations: Maintaining proper tire pressure and tread depth to improve fuel efficiency and prevent blowouts.

- Brake system checks: Regular inspections and servicing to prevent brake failures and ensure safe stopping distances.

- Fluid level checks: Monitoring and topping up fluids such as coolant, transmission fluid, and brake fluid to prevent overheating and component damage.

Consequences of Neglecting Preventive Maintenance

Preventive maintenance helps identify potential issues early on, preventing them from escalating into major problems that can lead to costly repairs and downtime. A lack of preventive maintenance can result in unexpected breakdowns, reduced fuel efficiency, increased repair costs, and safety risks for drivers and other road users.

By neglecting essential maintenance tasks, fleet managers risk compromising the reliability and performance of their vehicles, ultimately impacting the efficiency and profitability of their operations.

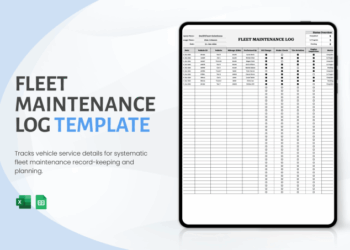

Inadequate Record-Keeping Practices

Maintaining accurate records for fleet maintenance is crucial for the smooth and efficient operation of any fleet. Without proper record-keeping practices, it becomes challenging to track maintenance schedules, identify recurring issues, and ensure compliance with regulations. Inadequate record-keeping can lead to increased downtime, unexpected breakdowns, and higher maintenance costs.

Significance of Maintaining Accurate Records

Effective record-keeping allows fleet managers to keep track of important maintenance tasks such as oil changes, tire rotations, and inspections. By documenting each maintenance activity, managers can establish a comprehensive maintenance history for each vehicle, enabling them to anticipate future maintenance needs accurately.

This proactive approach helps in preventing costly repairs and breakdowns, ultimately improving the overall reliability and longevity of the fleet.

Best Practices for Organizing and Managing Maintenance Records

- Utilize digital maintenance management systems (CMMS) for centralized record-keeping and easy access to maintenance history.

- Implement a standardized coding system for maintenance records to ensure consistency and easy retrieval of information.

- Regularly update maintenance records with detailed information on each service performed, including parts replaced, labor hours, and costs incurred.

- Archive old maintenance records securely for future reference and compliance purposes.

How Proper Record-Keeping Improves Maintenance Efficiency and Cost-Effectiveness

Proper record-keeping enhances maintenance efficiency by providing fleet managers with valuable insights into the performance of each vehicle. By analyzing maintenance records, managers can identify trends, predict potential issues, and optimize maintenance schedules to minimize downtime. Additionally, accurate records help in identifying warranty coverage, tracking maintenance costs, and evaluating the overall effectiveness of maintenance programs.

This data-driven approach enables fleet managers to make informed decisions, reduce unnecessary expenses, and maximize the operational lifespan of their vehicles.

Ignoring Manufacturer Guidelines

Ignoring manufacturer guidelines for vehicle maintenance can have serious consequences on the performance and longevity of your fleet. It is crucial to follow these guidelines to ensure that your vehicles operate efficiently and remain in optimal condition. Deviating from manufacturer recommendations can lead to increased repair costs, decreased fuel efficiency, and even safety hazards for drivers and passengers.

Impact on Vehicle Performance

- Failure to follow manufacturer guidelines for oil changes can result in engine damage and reduced fuel efficiency.

- Using the wrong type of fuel or lubricants can lead to engine malfunctions and costly repairs.

Impact on Vehicle Longevity

- Ignoring recommended maintenance intervals can shorten the lifespan of your vehicles and lead to premature wear and tear.

- Disregarding tire rotation and alignment recommendations can result in uneven tire wear and the need for frequent replacements.

Ensuring Compliance with Manufacturer Recommendations

- Regularly review and update your maintenance schedules based on manufacturer guidelines.

- Educate your fleet maintenance team on the importance of following manufacturer recommendations and provide training on specific maintenance procedures.

- Utilize fleet management software to track maintenance schedules and receive alerts when services are due.

Overlooking Driver Training

Driver training plays a crucial role in maintaining fleet vehicles by ensuring that drivers operate the vehicles correctly, follow recommended maintenance schedules, and promptly report any issues. Neglecting driver training can lead to increased wear and tear on vehicles, higher maintenance costs, and even safety risks for the drivers and others on the road.

Tips for Implementing Effective Driver Training Programs

- Provide comprehensive training on vehicle operation, maintenance procedures, and safety protocols.

- Offer regular refresher courses to keep drivers updated on best practices and new technologies.

- Incorporate hands-on training sessions to allow drivers to practice what they have learned.

- Utilize online training modules for convenient access and flexibility.

Benefits of Investing in Driver Education for Fleet Maintenance

- Reduced maintenance costs due to fewer breakdowns and repairs resulting from improved driver behavior.

- Increased vehicle lifespan by ensuring vehicles are driven and maintained properly.

- Enhanced safety for drivers and other road users, leading to fewer accidents and liabilities.

- Improved fuel efficiency through better driving habits and vehicle maintenance practices.

Last Recap

Concluding our discussion on Top Fleet Maintenance Mistakes and How to Avoid Them, this closing section encapsulates the key points and leaves readers with a lasting impression.

FAQ Insights

What are some consequences of ignoring preventive maintenance?

Ignoring preventive maintenance can lead to unexpected breakdowns, increased repair costs, and decreased overall fleet efficiency.

How can proper record-keeping practices benefit fleet maintenance?

Accurate record-keeping helps in tracking maintenance schedules, identifying recurring issues, and optimizing maintenance costs.

Why is it important to follow manufacturer guidelines for vehicle maintenance?

Manufacturer guidelines ensure optimal vehicle performance, warranty compliance, and longevity of fleet vehicles.

What role does driver training play in fleet maintenance?

Driver training reduces the likelihood of accidents, improves fuel efficiency, and prolongs the lifespan of fleet vehicles.